6 Lb. Polyisocyanurate Foam Sheets

Details

Details

Easy Carve for More Detailed Patterns and Molds

Our 6 lb./cubic foot Polyisocyanurate Foam is a rigid, closed-cell foam used in insulation, sandwich core, and carving applications where strength is key. The properties of this foam are similar to those of our 6 lb. Mix and Pour Foam (#624/625), so it can be easily cut and shaped with a sharp knife or sandpaper, and its density is suited to hold greater details.

- Glue sheets together to form thicker blocks for shaping functional, moldless parts.

- Store unused foam away from direct sunlight to avoid degradation.

- Temperature range: -300°F to 300°F

6 lb. Polyisocyanurate (PIR) foam sheets are a specific density variant of PIR foam that can be used in composites. Here is some information about the use of 6 lb. PIR foam sheets in composites:

- Density and Strength: The density of 6 lb. PIR foam sheets refers to the weight of the foam per cubic foot. A higher density foam offers increased strength and durability compared to lower density foams. The 6 lb. density indicates that the foam is relatively dense and can provide good structural support in composite applications.

- Core Material in Sandwich Structures: Similar to other PIR foam sheets, 6 lb. PIR foam sheets are often used as a core material in sandwich structures. Sandwich panels constructed with 6 lb. PIR foam as the core offer improved strength and stiffness compared to lower density foams. The high density helps to provide structural integrity to the composite component.

- Thermal Insulation: PIR foam sheets, including 6 lb. density, exhibit excellent thermal insulation properties. This makes them suitable for applications where thermal efficiency is important, such as in building insulation or temperature-sensitive composite structures.

- Bonding: Like other PIR foam sheets, 6 lb. PIR foam can be bonded to itself and other composite materials using compatible adhesives or bonding techniques. Ensuring a strong bond between the foam and other composite layers is crucial for the overall integrity of the composite structure.

- Machining and Shaping: 6 lb. PIR foam sheets can be easily machined and shaped using appropriate cutting tools and techniques. CNC machining can be employed to achieve precise cuts, contours, and profiles as per the design requirements of the composite component.

- Compatibility with Resins: 6 lb. PIR foam sheets are compatible with various resin systems commonly used in composites, such as polyester, vinyl ester, and epoxy resins. However, it is important to verify compatibility and ensure proper adhesion between the foam and resin by using appropriate adhesives or primers if necessary.

- Fire Resistance: PIR foam sheets, including 6 lb. density, exhibit good fire resistance properties. They have a relatively high ignition temperature and low flame spread characteristics, making them suitable for applications where fire safety is a concern.

When using 6 lb. PIR foam sheets in composites, it is essential to follow the manufacturer's guidelines and recommendations regarding storage, handling, cutting, bonding, and compatibility with specific resin systems. Proper surface preparation, adhesive selection, and processing techniques are important factors in achieving high-quality and reliable composite structures.

Data Sheets

Data Sheets

Shipping

Shipping

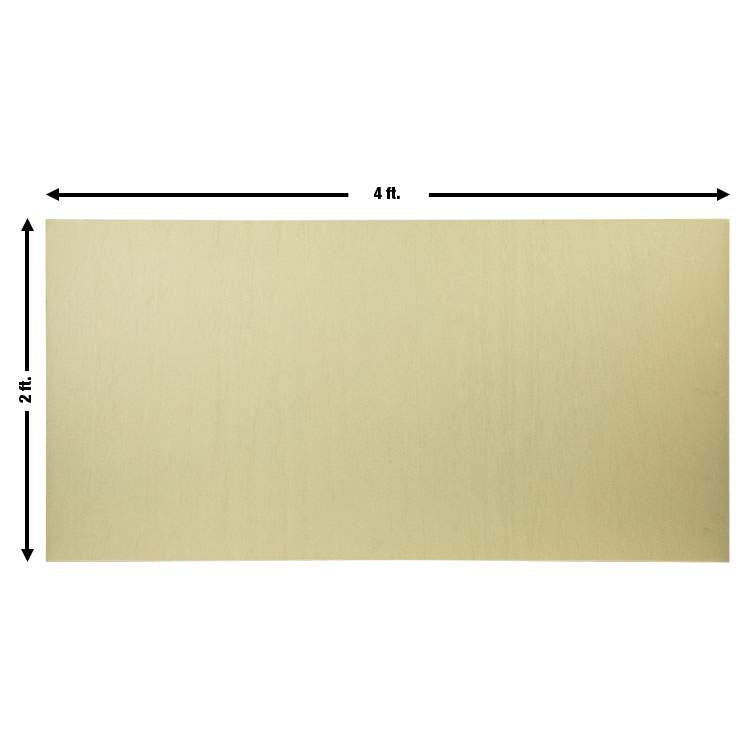

Sizes

Sizes

Pricing

Collapsible content

Videos

Reviews

Excellent foam for carving new console