Photo credit IStock Photo.

Photo credit IStock Photo.

Over the past fifty years, Fibre Glast Developments has supplied thousands of new customers with materials they had never seen, and taught them to use them successfully. However, we rarely discuss the lessons we have learned about organizing the composite shop itself. One of the most challenging hurdles a fabricator will face is just "how" to begin. This includes setting up their first composites shop.

Over the past fifty years, Fibre Glast Developments has supplied thousands of new customers with materials they had never seen, and taught them to use them successfully. However, we rarely discuss the lessons we have learned about organizing the composite shop itself. One of the most challenging hurdles a fabricator will face is just "how" to begin. This includes setting up their first composites shop.

In the "Perfect" environment, there are always plenty of spaces to work, warm temperatures to quickly cure resin, and no fumes. In reality, most shops are cramped, dark and dirty. The ideal composite shop should be safe, clean, and well ventilated. To keep the work fun and comfortable, cutting racks and benches can also be built to store materials and hold molds at appropriate working heights. Safety is one of the most important features for any fabricator, so lets take a look at some of the most common products you might find within a properly run composites shop.

Make Safety First

Photo credit IStock Photo.

Photo credit IStock Photo.

Composite materials can be quite safe when handled properly. All products should contain safety and general handling instructions on their material containers, make sure you are familiar and follow these practices at all times. You may also wish to check the Safety Data Sheet (SDS) for each product, for further information. In general, limit personal exposure to the chemical resins by wearing gloves, safety glasses, an organic vapor respirator and protective clothing while handling them. If exposure does occur, quickly wash with soap and water. Finally, sanding and grinding dust must be kept out of the lungs. Always wear a respirator during the finishing steps, and vacuum up dust as it is created.

Safety Product Examples

| Name |

Description |

|

| Organic Vapor Respirator |

Wearing a Vapor Respirator will protect fabricators from dust, fumes, vapors and gases. Vapor cartridges contain granulated charcoal treated to absorb organic vapors that pass through with the air you inhale. |

|

| Safety Goggles |

In order to protect fabricators eyes from vapors, chemicals and other substances, fabricators must wear a pair of impact resistant safety goggles. These goggles come with a polycarbonate coated lens that helps resist impacts and nearly 100% of harmful UVA/UVB rays. |

|

| Flock lined Latex Gloves |

While standard latex and vinyl gloves are good for some projects, these flock lined latex gloves are thicker, heavy-duty and just right for protecting your hands from any resins or solvents. They can also be cleaned for more than one use, or pitched after the project is complete. |

|

| Disposable body Suit |

Laminating can be a dirty job. This maxshield made disposable body suit offers a double layer of full-body protection that holds off dirt, aerosols, spills and splashes. |

|

Proper Ventilation and Temperatures

Photo credit IStock Photo.

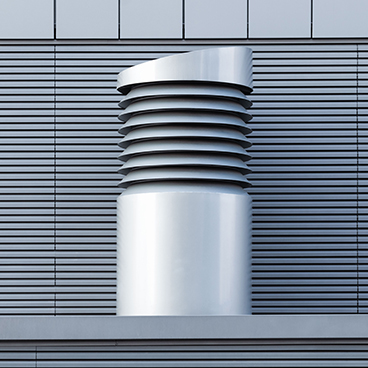

Photo credit IStock Photo. Anyone who has ever worked with

polyester resin in a closed room knows how overwhelming the fumes can be. Ventilation may be obvious with polyester resin, but it is just as important with

epoxy. Some individuals are extremely sensitive to epoxy, and high concentrations of fumes can be enough to severely irritate the skin. If the lungs become irritated and inflamed, the affected individual may need immediate medical attention. Furthermore, sensitization can be developed over time in individuals who showed no previous reaction. This bleak picture can be eliminated with simple planning. An exhaust fan blowing out of a window near the workstation will often suffice. As the jobs get larger so do the ventilation demands. Make sure that an inlet source of fresh air is also available to create a cross-draft. Unfortunately, the cross-draft will cool a room during the winter months in most parts of the country. It will be necessary to maintain both ventilation and optimum resin curing temperature in the workshop to achieve good results. This is not the time to try to save on the heating bill. Maintain temperatures as specified on the product labels, or wait until the conditions warm up.

Keep it Clean and Organized

Photo credit IStock Photo.

Photo credit IStock Photo. General cleanliness and organization will save both time and money. Fiberglass and composite work can be a dirty job. However, at many professional facilities, the work areas are spotless. It appears that this is achieved in two ways. First, as much dust as possible is collected at the source. Tool guards with built in vacuum attachments are available and are the best way to contain dust. If this equipment is not used, simply tape the hose of a shop vac to the work surface. The vacuum will remove much of the mess.

The second way professionals control contamination is to physically separate the various procedural steps of the lamination process. Most companies have clean rooms where reinforcing fabrics and vacuum bagging materials are stored, cut and handled. These materials are generally the most expensive and easily ruined, so building the storage racks and cutting tables is well warranted. Grinding and finishing are also separated for obvious reasons. If space is not a problem, set up a third room for laminating. If this is not possible, double up in the grinding area. Just don't expect to perform both tasks simultaneously. The clean room should remain just that: clean.

Get Comfortable

Being comfortable in your work environment can be more important than you realize. Larger scale projects can be brutal on the back and arms due to the repetitive motions and distances which must be covered within molds. When building risers or benches to hold molds, make sure they are at comfortable working heights for the fabrication process.

A comfortable and well lit work environment leads to better parts and quicker fabrication. A final recommendation is to build a fabric rack and cutting table for storing and handling reinforcement. Better yet, combine them. A fabric rack that has a cutting table hinged to it is a great way to save space. When it is not needed, the table folds up and out of the way much like a wall mounted ironing board or day bed. When the table is folded up it also protects the fabric from dust, UV light, and other contaminants. The bars of the rack can be made from closet rods or water pipe, and slipped through holes on the sides of the rack. Keep in mind that most reinforcements are available up to 60 inches wide. Your table needs to be as wide as your widest fabric. Fabric stored and protected in this way will have a much longer shelf-life. Below, you can find some of the fabric racks and work

A comfortable and well lit work environment leads to better parts and quicker fabrication. A final recommendation is to build a fabric rack and cutting table for storing and handling reinforcement. Better yet, combine them. A fabric rack that has a cutting table hinged to it is a great way to save space. When it is not needed, the table folds up and out of the way much like a wall mounted ironing board or day bed. When the table is folded up it also protects the fabric from dust, UV light, and other contaminants. The bars of the rack can be made from closet rods or water pipe, and slipped through holes on the sides of the rack. Keep in mind that most reinforcements are available up to 60 inches wide. Your table needs to be as wide as your widest fabric. Fabric stored and protected in this way will have a much longer shelf-life. Below, you can find some of the fabric racks and work

Fabric Racks and Work Stations

| Name |

Description |

|

| Fabric Racks |

Fabric racks are designed to keep your composites shop in order, keeping each roll of fabric safely stored and easy to measure out for each project. Each of Fibre Glast's fabric racks are durably built, and are suitable for up to 60" width fabrics. |

|

| Cutting Station |

This composite cutting station is ideal for cutting your composite fabrics, with a tension bar and guide that will keep the fabric smooth and even through the cutting process. |

|

| Complete Work Station |

An all in one design, the complete composites work station allows for storage of materials, fabric and supplies all in one. The extra large work table allows for plenty of room to work, with a tension guide and bar to keep your fabric clean and straight while working. |

|

Conclusion

To some, these suggestions may appear quite obvious. This subject was selected to help newcomers get off to the right start, but hopefully there are some organizational hints that everyone will wish to incorporate. To continue to gain the amazing advantages of composites for years to come, workers must respect the materials and take certain precautions now. This organization actually improves the comfort of working with composite materials and the quality of the finished parts. Begin planning like a professional and the results will be professional as well!