Thixotropic Silica

Details

Details

Prevent Sags on Vertical Surfaces

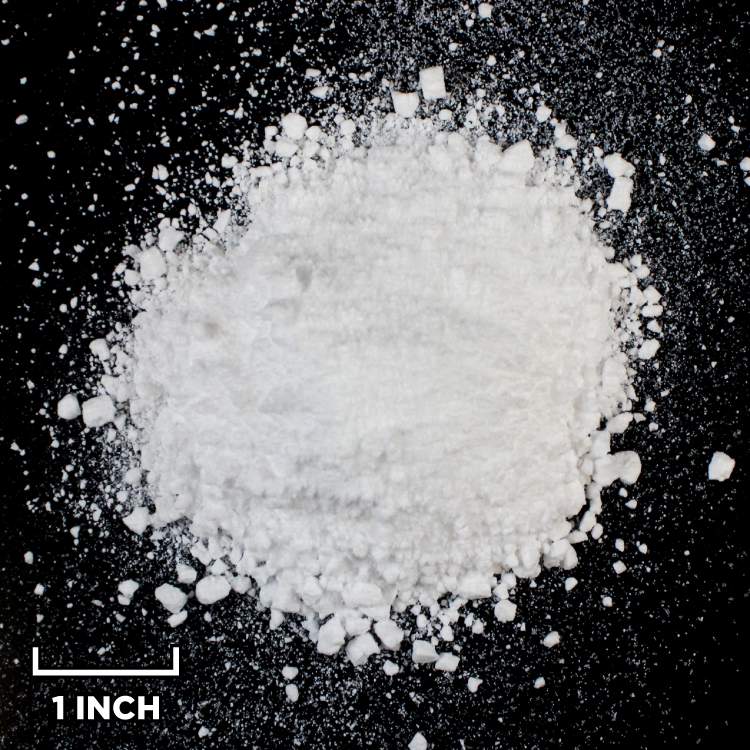

A white, free-flowing powder, Thixotropic Silica is a thickening agent primarily added to resin to prevent run-off and sags on vertical surfaces.

- Use with an epoxy to produce extremely hard, solid parts, perfect for structural bonding, filling, and filleting.

- Use in conjunction with chopped glass fiber for added strength for parts.

- Silica-filled resin can be difficult to sand. Consider using #22 Glass Microspheres for areas that require sanding.

This filler is compatible with epoxy, polyester, and vinyl ester resin systems. Add filler after adding catalyst to resin.

Mix ratio is 1:2 (filler to resin by volume) for general use, 1:3 (filler to resin by volume) to reduce runs/sagging.

Thixotropic silica, also known as fumed silica or colloidal silica, is a type of fine, high-surface-area silica powder that exhibits thixotropic (viscosity that decreases when shear stress is applied and gradual recovery when stress is removed) properties. Thixotropic silica is commonly used as a thickening and thixotropic agent in various applications, including composites. Here is some information about its use in composites:

- Thickening and Rheology Control: Thixotropic silica is often added to composite materials, such as resins or gel coats, to increase their viscosity and control their rheological (deformation and flow) properties. It helps prevent sagging and dripping during application, allowing for better control and easier handling of the material.

- Reinforcement: Thixotropic silica can act as a reinforcing filler in composites, enhancing their mechanical properties. When incorporated into resin systems, it can improve the tensile strength, flexural strength, and impact resistance of the composite material.

- Improved Thixotropy: Thixotropic silica imparts thixotropic behavior to composite materials. Thixotropy refers to the property of becoming less viscous when subjected to shear stress and returning to a higher viscosity when the stress is removed. This behavior is beneficial during application, as it allows the material to flow and be spread easily, but it maintains stability and prevents excessive flow or sagging.

- Sag Resistance: The addition of thixotropic silica in composites can improve their resistance to sagging or slumping when applied on vertical or overhead surfaces. This is particularly useful in applications where the material needs to adhere to vertical or inclined surfaces without significant deformation.

- Improved Adhesion: Thixotropic silica can enhance the adhesion properties of composites by providing a tacky or sticky surface. This helps improve the bond strength between layers of composite materials or between the composite and other substrates.

- Surface Smoothing: Thixotropic silica can contribute to the surface smoothness of composites by filling voids, pinholes, or imperfections. It helps create a more uniform and aesthetically pleasing surface finish.

- Improved Workability: The addition of thixotropic silica can improve the workability and handling characteristics of composite materials. It can make the material easier to mix, apply, and shape, allowing for better control and precision during the fabrication process.

It is important to note that the specific amount of thixotropic silica and its influence on the properties of the composite will depend on various factors, including the desired viscosity, application method, curing process, and the resin system used.

Data Sheets

Data Sheets

Shipping

Shipping

Sizes

Sizes

Collapsible content

Videos

Reviews

When using the Thixotropic silica to bond a horizontal bulkhead to nearly vertical sides of my sailboat hull interior we had considerable difficulty due to the low viscosity of the mix at the recommended ratio of 3:1. We did not prepare a test batch before hand and therefore did not plan to use clay or some other form of a dam to control the slumping of the mix. Ended up using masking tape on the underside surface but it was quite a mess as a result. Perhaps the ratio needs to be reviewed or additional thickening agents should have been added for a vertical installation.

We use it for general bonding of composite to composite and aluminum to composite. Very smooth and easy to mix to any viscosity ranging from catsup to peanut butter. The exceptionally smooth nature of the silica powder results in a stronger and less porous bonding filler than we've seen from West System colloidal silica or other silica fillers.