2 Lb. Polyurethane Mix and Pour Foam

Details

Details

Fill Cavities for Flotation and Reinforcement

This 2 lb. density foam comes as a two-part kit, both parts equally mixed. It is a closed-cell system, meaning individual cells of foam trap in air and keep liquids out. As a result, it is most frequently used for flotation applications, delivering 60 pounds of float per cubic foot. It can be used to fill cavities for reinforcement and insulation, and can be shaped or carved, once cured, for use as a plug in mold-making or sculpting

Features

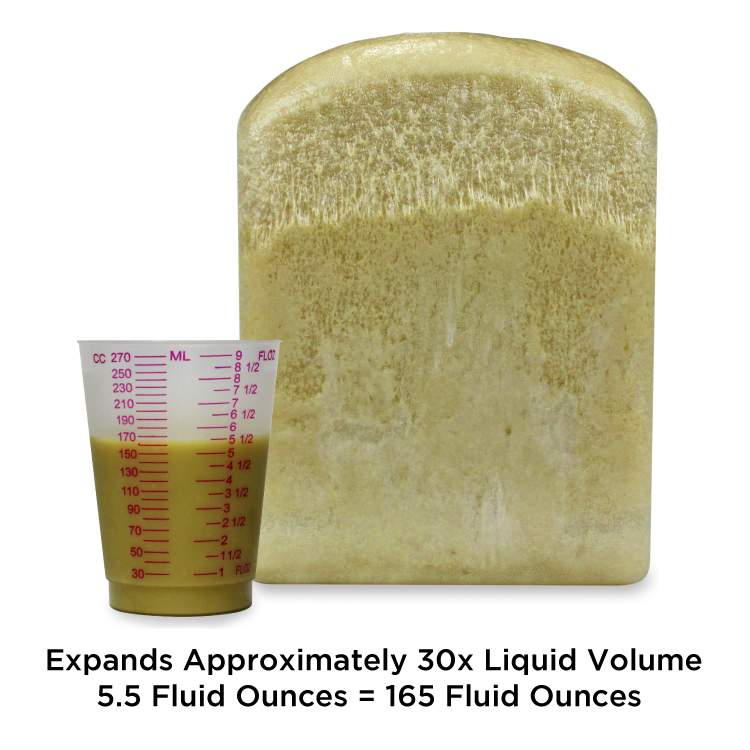

- 2 lb. foam expands approximately 30 times its liquid volume before cure, and can fill any shape.

- Closed-cell structure does not react with oil or gasoline, and will not absorb water.

- Laminate directly onto foam using epoxy or polyester resin.

- Can be pigmented with urethane pigments (#141, #143).

- Also compatible with latex paint, and in-mold parting wax (#1016).

- This foam is designed to meet USCG Title 33, Chapter 1, Part 183 when mixed properly.

Mix Ratio

- Mix Ratio: 1:1 by Volume

Tips

- Once two parts are mixed, it will begin to react and expand within 45 seconds, and will continue for several minutes.

- Before filling cavities for insulation, flotation or reinforcement, determine how much foam you'll need. First, calculate the volume of your container in cubic feet. For example 1 ft. high x 1 ft. long x 2 ft. deep = 2 total cubic feet. Second, for 2 lb. foam, multiply that total by 2.5. In this case, 2 cubic ft. x 2.5 = 5 lb. of required foam.

- Utilize small pours to prevent expansion damage, waiting 15-20 minutes between each pour

- The foam will exert approximately 2-4 PSI expansion pressure during void fill; for a completely closed mold, expansion pressure can reach 4-6 PSI.

Specifications

|

Appearance |

Dark brown liquid (25); Amber liquid (24) |

|

Thermal Resistance |

R-4.76 per inch |

|

Max Working Temperature |

200°F |

|

Flotation |

60lbs per cubic foot |

|

Compressive Strength |

34 psi |

|

Tensile Strength |

52 PSI |

Guarantee

Fibre Glast is committed to ensuring that every chemical we offer is manufactured to the highest standards, so that you can expect the same properties and quality every time you order.

Click here for more information on our First Quality Guarantee.

Data Sheets

Data Sheets

Shipping

Shipping

Sizes

Sizes

Collapsible content

Videos

Reviews

This stuff rocked !!! Super fun to play and experiment with. I used this product to fill empty space, and shape my damaged paddle board. The foam was easy to mold (with patience), easy to cut / sculpt, and sanded with ease. I will certainly use your products in the future.

I give FiberGlast a 5 star rating. Any products I have ordered are of professional quality and I say that as a retired boat builder and fiberglass tech through various periods of my career. My orders have been shipped (extremely) promptly and packaged with great care, and their pricing is at least comparable if not better than a local supplier in my area. The best advantage is that since I live retired on a boat in a marina, pier side delivery makes life so much simpler. I literally have no cons to list in dealing with this company.

I thank Fibreglast for wide knowledge base and personal customer service. I left a message with customer service on a Sunday night and they returned my call first thing Monday morning. I am opening a new business called Ahead of the Carve. I make designer hand-carved and crafted foam pumpkins for every Occasion, Season, or Reason. A customer service sales expert walked me through the correct products to buy and helped me with steps to make a mold for all the pumpkins I sell. Having this fiberglass mold enabled me to cut my expense of crafting each pumpkin in half, which has widened my profit margin. An investment well spent!Thanks!Ann

2 Lb. Polyurethane Mix and Pour Foam - 19.3 lb. (9 cubic feet) product review. This product did exactly what I expected it to do - exactly what I'm used to it doing using it in production boat building of HeneryO boats in North Carolina.

I used to buy polyurethane foam, carbon fiber, and other composite products from a local supplier but was discouraged by high prices and quality issues.Once I started buying from Fibreglast I realized I could depend on consistently high quality foam products with no mixing issues, excellent results every time. The vacuum forming products also work very well and the instructional videos have been incredibly helpful in de-mystifying the vacuum assisted processes.